Consider a sheet with a 20 mm thickness and a length of 300 mm as shown in figure 1.

Sheet metal bend relief formula.

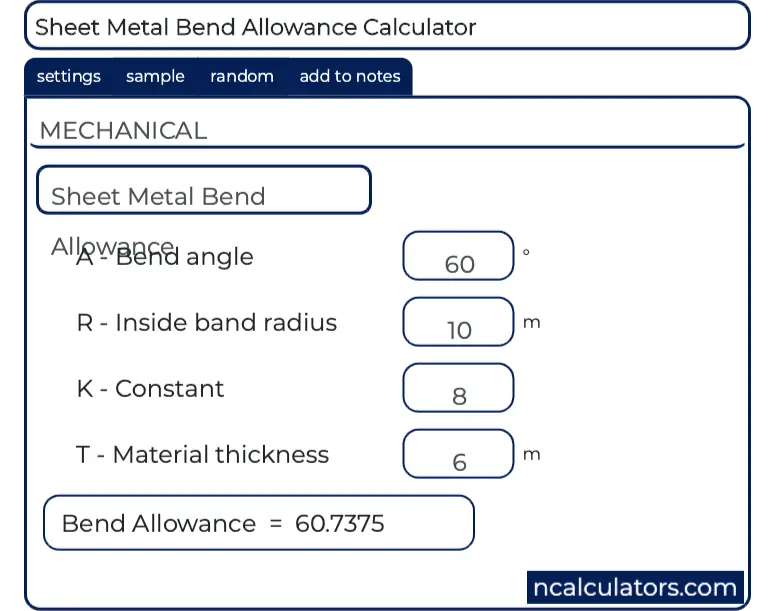

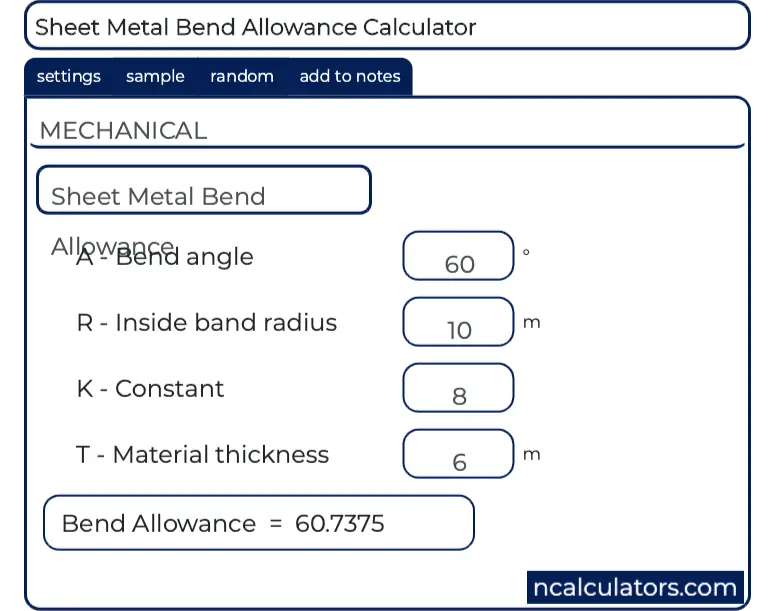

You will need to know your material thickness mt the bend angle b the inside radius ir and the k factor k.

The diagram shows one such mechanism.

ß bending angle for bends between 90 and 165 degrees the formula is.

The bend allowance describes the length of the neutral axis between the bend lines or in other words the arc length of the bend.

D 2 5t r see below the height can be less but it required secondary operations and is far more costly.

In general a minimum bend relief is equal to the material thickness plus the inside bend radius.

The material thickness will be measured in decimal form not by the gauge number.

When sheet metal makes a transition from a bend to a flat surface or to another bend it tends to rip and tear.

Most sheet metal materials will conform to the calculations.

Refer to the chart for values for folder as well as various press brake tooling combinations.

The following illustration shows the equation calculation for determining the bend allowance when forming sheet metal.

We are going to review three bending scenarios with three different bending angles.

For bends between 0 and 90 degrees the formula is as follows.

The bend allowance formula takes into account the geometries of bending and the properties of your metal to determine the bend allowance.

Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend.

Geometry of tooling imposes a minimum bend dimension.

Therefore the bend allowance added to the flange lengths is equal to the total flat length.

For bends over 165 there is no need to calculate bend allowances as the neutral axis stays pretty much in the middle of the detail.

This page also includes a link to a on line sheet metal bend allowance calculator.

Sheet metal calculator bend allowance equations and calculator.

5 edge distortion an exaggerated example of edge deformation is pictured in figure a below.

Form height to thickness ratio to determine the minimum form height for sheet metal use the following formula.