The sliding sleeve separation tool enables flow from the casing and tubing annulus through an open sliding sleeve and up the production tubing while blanking off the tubing just below the sliding sleeve.

Sliding sleeve door ssd.

The ssd can be combined with tendeka s inflow technologies to provide inflow control when in the open position.

What is shorthand of sliding sleeve door.

You can also look at abbreviations and acronyms with word ssd in term.

It incorporates an internal sleeve that when open enables communication between the tubing and tubing casing annulus.

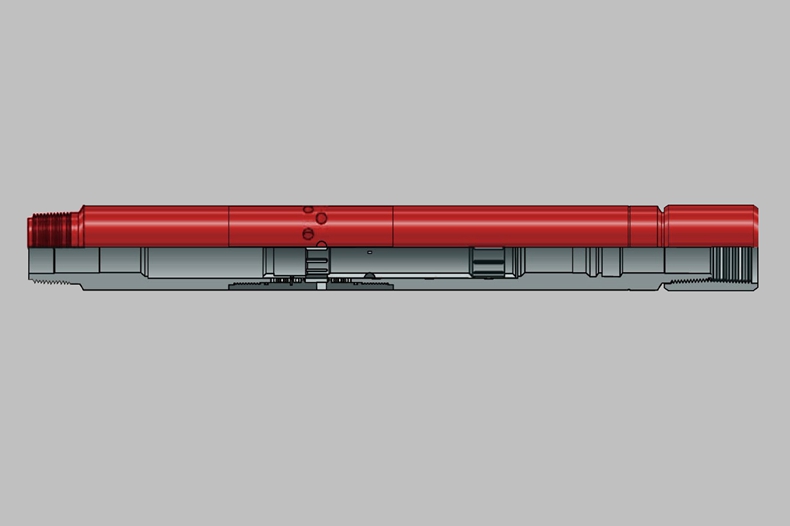

Sliding side door sleeves are a robust and reliable method of isolating the tubing id from the reservoir for a variety of reasons including but not limited to fluid loss control activation of hydraulically set down hole tools zonal stimulation and production and icd shutoff for ultimate production control.

The durasleeve sliding side door circulating and production sleeve is a full opening device that can be operated using standard slickline methods.

Weatherford s optisleeve sliding sleeve is a tubing mounted device used to regulate flow from individual producing zones or to control communication between the tubing and the annulus.

This allows alternating production of two zones isolated from each other by packers without commingling.

What does ssd stand for.

It has seal bores above and below the ports and a top no go shoulder and locking groove.

The act model l sliding sleeve is a downhole tool used to establish communication when desired between the tubing and annulus.

Ssd abbreviation stands for sliding sleeve door.

Selective and or top no go locking devices are available for use with the sleeve.

The most common shorthand of sliding sleeve door is ssd.

Sliding side door ssd open close sliding sleeve ssd enabling selective flow for production and injection applications.

The tool has one connection which minimizes potential leak paths the non elastomeric seal.